SURGYSTER - DRY

One Chamber, Many Tasks...

ETHYLENE OXIDE STERILIZATION & VACUUM DRYING COMBINED MACHINE

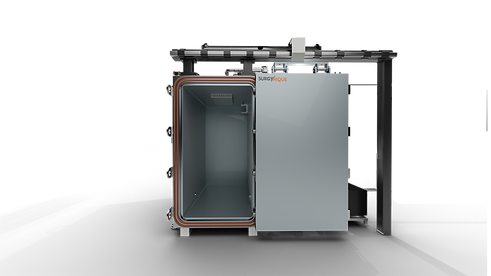

The sterilization chamber serves as the core component of the sterilizer system. It is a specially designed pressure-rated vessel where the operator loads pallets containing products—commonly referred to as the load—to undergo the sterilization process. Engineered to maintain strict environmental parameters such as temperature, pressure, and humidity, the chamber ensures uniform and eective sterilization throughout the entire load. Its robust construction and high-grade materials allow it to withstand the demanding conditions required for sterilization, ensuring both product safety and compliance with industry regulations. Additionally, the chamber often includes integrated sensors and monitoring systems to provide real-time feedback

Chamber Unit

The chamber is constructed with a sturdy and innovative mechanical design, using 316L stainless steel and reinforced with U-shaped 304 grade stainless steel beams. Its unique feature lies in being designed independently from all other units, allowing it to be kept solely within a clean room environment, thereby optimizing space efficiency. For thermal efficiency, the chamber is insulated with 20 mm thick rock wool and covered with aluminum panels, topped with an aluminum deck.

The device is designed according to international safety standards with cutting edge technology. All units functioning in the machine are modular. This is important since any maintanence process should be easy and the manufacturers should have continuous operation.

Recirculation System

The chamber recirculation system is an integral part of the sterilization chamber, typically consisting of a high-performance fan installed within the chamber. This system draws air or gas from an inlet located at the top of the chamber and redistributes it through one or more outlets positioned at the bottom, generally on the opposite side of the inlet. The primary function of the recirculation system is to ensure continuous and uniform mixing of the sterilizing gas within the chamber.

By promoting consistent circulation, the system helps maintain a homogeneous distribution of critical parameters such as temperature, relative humidity, and ethylene oxide (EO) concentration throughout the entire load. This uniformity is essential for achieving effective sterilization results and ensuring process reliability and validation compliance.

Unique Closed-Loop Blower Powered Gas Recirculation System

Homogenous Gas and Temperature Distribution

Quicker Heat Transfer to the products

Better exposure to EO gas

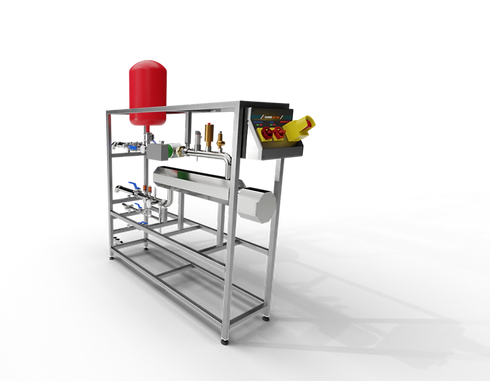

Heat Skids Unit

This Unit controls the water jacket temperature according to the sensor feed back from the cabin

The system Works as closed curcuit

The water temperature is limited for safety

The resistance power and flow rates are controlled

Atex certified components

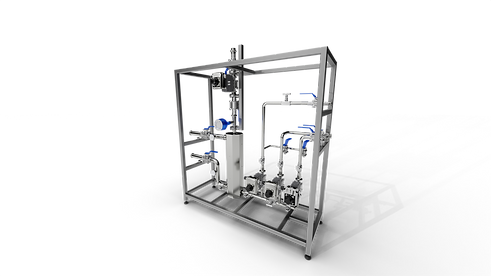

Vaporizer

This Unit heats the EO and Nitrogen gases

It provides the freezing risk of gases

It is safe because the heating mechanism

It provides the freezing risk of gases It is safe because the heating mechanism is hot water

The pressure and temperature is continuosly monitored

Atex certified components

Steam Generator

This Unit is for controlling the humidity in the chamber

Temperature and water level control

Pressure relieve valve for safety It is equipped with Pressure and Temperature Sensors & Switches

Automatic level indication and filling

Atex certified components

Vacuum Unit

A two-stage vacuum system ensures rapid evacuation and deep vacuum performance

ATEX-compliant pump

for Drying

Dry Screw Vacuum Pump

for Sterilization

Liquid Ring Vacuum Pump